harga mesin pelletizer PE PP

Katerangan

Mesin pelletizer palastik nyaéta prosés ngarobah plastik kana granules. Dina operasi, polimér ngalembereh dibagi kana cingcin tina untaian anu ngalir ngaliwatan annular paeh kana chamber motong banjir ku cai prosés. A sirah motong puteran dina aliran cai motong untaian polimér kana pellets, nu langsung conveyed kaluar tina chamber motong.

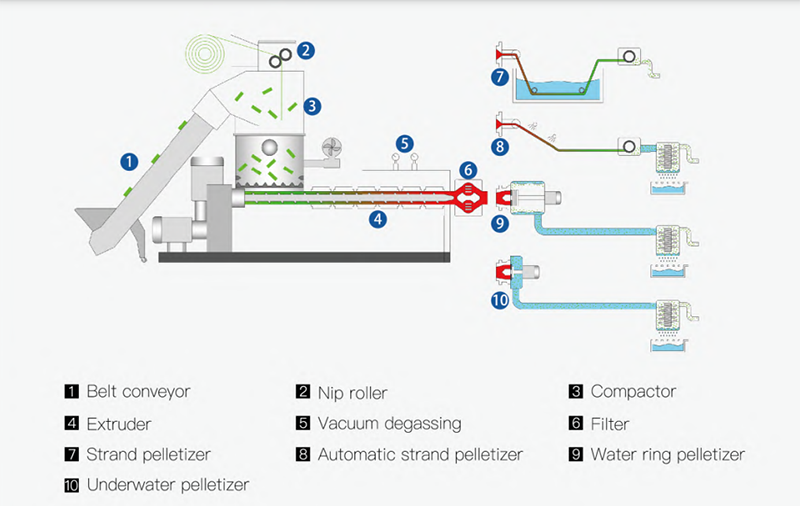

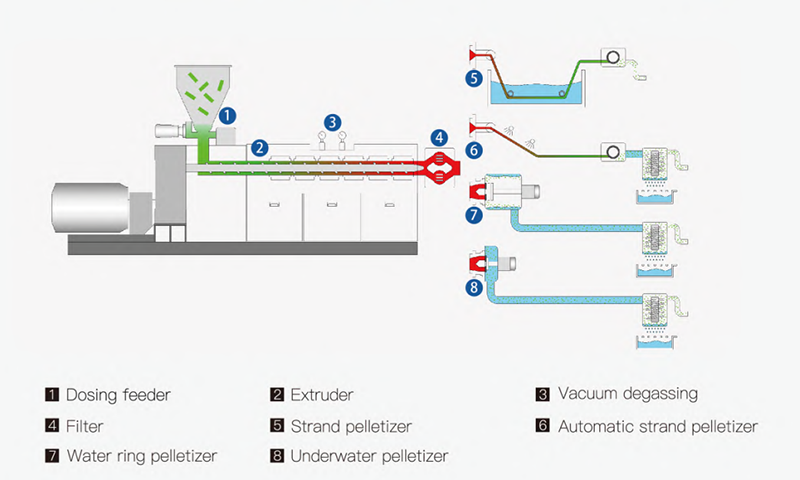

pabrik pelletizing palastik bisa ngaropéa sakumaha tunggal (ngan hiji mesin Tonjolan) jeung susunan tahap ganda (hiji mesin Tonjolan utama sarta hiji mesin Tonjolan sekundér leutik).

"Hot Cut" water-ring die face pelletizing and "Cold Cut" strand pelletizing method are available gumantung kana karesep anjeun.

Ngalembereh pelletizing (hot cut): ngalembereh asalna tina paeh anu ampir geuwat potong pellets nu conveyed tur tiis ku cair atawa gas;

Strand pelletizing (tiis cut): ngalembereh asalna tina sirah paeh dirobah jadi untaian nu motong kana pellets sanggeus cooling na solidification.

Urang tiasa ngadamel mesin pelletizer alus keur anjeun kalawan harga mesin pelletizer alus.

Rincian

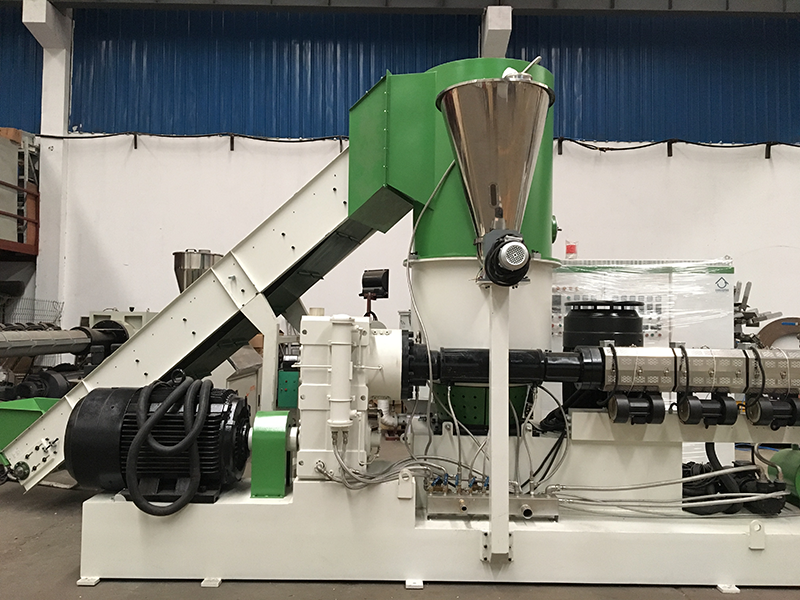

Unit Compactor

Kombinasi wilah rotatory speed tinggi na wilah cicing quickens laju compacting sarta ngarahkeun bahan kana screws extruder.

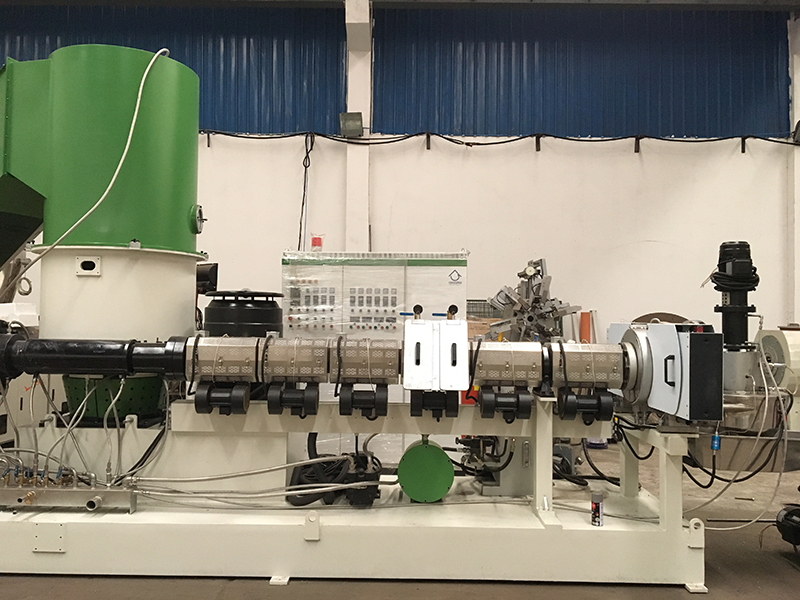

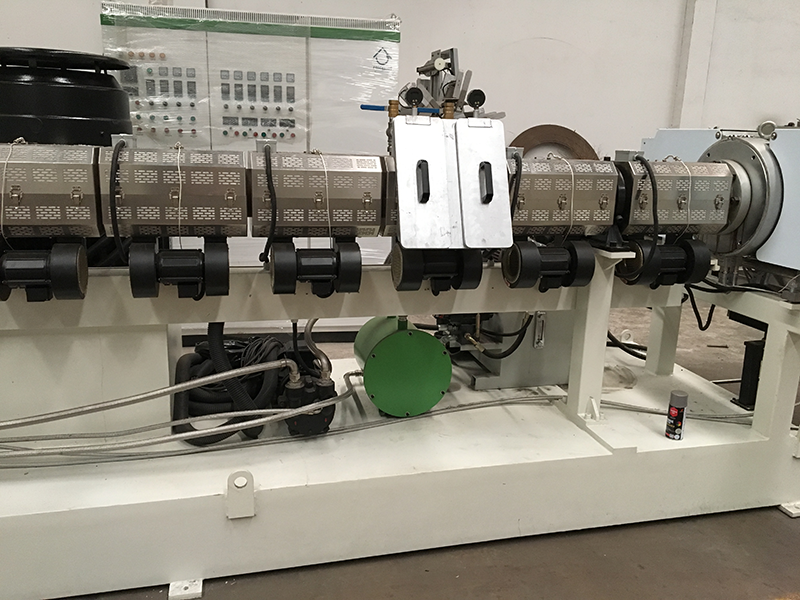

Unit Extruder

A extruder screw tunggal husus dilarapkeun ka gently ngalembereh bahan pre-compacted.

The scraps palastik bakal ogé dilebur, plasticized di extruder nu.

Laras efisien tinggi na screw dipaké pikeun extruder kalawan hasil plasticizing alus teuing jeung kapasitas kaluaran tinggi, ngadopsi bahan alloy tahan maké tinggi pikeun mastikeun 1,5 kali hirup jasa tina hiji normal.

Unit degassing

Kalawan sistem degassing vakum zone ganda, paling volatiles bisa dihapus éféktif, utamana pilem dicitak beurat jeung bahan kalawan sababaraha eusi cai.

Nyaring

Tipe piring, tipe pistion sarta otomatis timer beberesih tipe filter, pilihan Béda nurutkeun eusi impurity dina bahan jeung kabiasaan klien urang.

Saringan tipe plat nyaéta ongkos-éféktif jeung gampang beroperasi nu utamana dipaké pikeun thermoplastic biasa sakumaha biasa

solusi filtration.

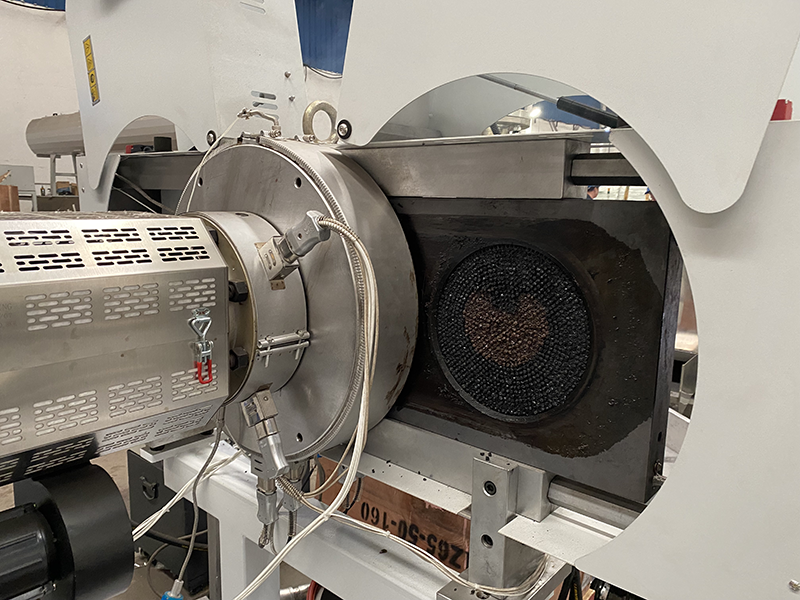

Pelletizer ring cai

Laju motong pelletizer dikawasa sacara otomatis ku PLC dumasar kana tekanan sirah paeh, anu tiasa ngahontal ukuran seragam pikeun pellets kaluaran.

Agul of pelletizer touch ka paeh plat otomatis ku sistem pneumatic, pastikeun wilah

kontak sareng piring paeh leres, gampang dioperasikeun sareng abrasion dihindari.

Data Téknis

| Tipe | KCP80 | KCP100 | KCP120 | KCP140 | KCP160 | KCP180 | |

| Kapasitas (kg/h) | 150-250 | 300-420 | 400-600 | 600-750 | 800-950 | 1000-1200 | |

| Konsumsi énergi (kWh/kg) | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | |

| Compactor | Volume (L) | 300 | 500 | 800 | 1000 | 1200 | 1400 |

| Daya Motor (kw) | 37-45 | 55-75 | 75-90 | 90-132 | 132-160 | 160-185 | |

| Extruder | Diaméter screw (mm) | φ80 | φ100 | φ120 | φ140 | φ160 | φ180 |

| L/D | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | |

| Daya motor (kw) | 55-75 | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

| Filter (pilihan) | Tipe plat dua posisi | ● | ● | ● | ● | ● | ● |

| Tipe piston dua posisi | ○ | ○ | ○ | ○ | ○ | ○ | |

| Tipe piston siram deui | ○ | ○ | ○ | ○ | ○ | ○ | |

| Tipe ngabersihan diri otomatis | ○ | ○ | ○ | ○ | ○ | ○ | |

| 2nd Extruder (opsional) | Diaméter screw (mm) | φ100 | φ120 | φ150 | φ150 | φ180 | φ200 |

| L/D | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Daya motor (kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 110-160 | |

| Hilir (pilihan) | Pelletizer ring cai | ● | ● | ● | ● | ● | ● |

| Strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Pelletizer strand otomatis | ○ | ○ | ○ | ○ | ○ | ○ | |

| Pelletizer jero cai | ○ | ○ | ○ | ○ | ○ | ○ | |

● baku ○ alternatif